If you’ve had a mildly deep touch with the western media, or have lived in the USA, you are probably at least somewhat already familiar with the concept of a person picking up their delivery parcel within some “randomly” placed locker that’s meant for picking up delivered goods on your own.

Now prepare yourselves for a fact check: Europe has mastered it in the last decade.

We are going to take a look at Croatian Post (hereinafter referred to as HP, the Croatian abbreviation), a national postal operator of the Republic of Croatia and their new service by the means of a self-pickup functioning parcel locker called the Paketomat.

How did HP digitize their newly introduced technology for the market by connecting it with the ever growing e-commerce that’s currently at its peak? Learn more about the topic in this case study.

Scratching a surface

For starters, let’s justify the broad statement in the first paragraph, saying that Europe has mastered it throughout the last decade.

Germany, a country equivalent to approximately 85 percent the size of California, possesses 3,400 Packstation networks, with 8 million registered customers! There’s 340,000 compartments in over 1,600 cities. As such, it takes only 10 minutes or less for 90 percent of the population in Germany to reach one, according to Seeking Alpha.

Take a moment to digest that. With the current situation as a prediction for the future, the Europeans will be spoiled with their options of package distribution at hand.

That very similar design and system is used by the main Croatian postal operator, HP. There are 131 Paketomat machines split equally across the country, introduced in 2021, the year of the Pandemic, where we all witnessed how contactless delivery was a thing.

Modern ways introduce modern problems

Another novelty just knocked on the doors, or some would just call it a new problem for the postal industry, depending how you look at things. It is the decentralization of the main warehouses.

According to the Parcel and Postal Technology International, for a modern and well-adapted logistics operation, the focus must be on the final mile.

By 2023, it is estimated that 50% of all e-commerce orders will be filled through local fulfillment. With local fulfilment comes local delivery, and the industry must adapt itself to this reality. Immense access to data and technology enables companies to quickly analyze and optimize their workflows, but only if they have the tools. With data comes knowledge, but only if it is used correctly.

That is the driving ideology behind digital transformation, and digital transformation is where the industry leaders are spending their time and money now for the future.

Let’s simplify the issue here. If you have, for example, a main warehouse in the city capital, you as a subordinated post office present point A as a place of receiving the parcels. Now what you do as a team of postmen is going from point A to multiple point B’s, delivering customers their parcels.

But, as decentralization of the main warehouses becomes a thing, you no longer have a fixed point A. What you need to do now is circle around multiple point A’s collecting parcels, then visiting multiple point B’s dropping those. As it presents savings for some companies having decentralized warehouses, the local postal offices are left more and more without their core HQ’s, the point A’s.

That paradigm shift leaves them with the rising cost of time, workforce and transportation.

Therefore, somewhat of a solution occurred as an attempt to produce a kind of “nest” for harvesting packages. We can say that those hot spots for postmen would be to just leave the cluster of parcels in a single hotspot location – the Paketomat locker, instead of delivering every single one to custom locations around the city.

This will take time to be accepted fully, but time will bring out the best of it. For now it is only an option, but a well received one already.

Arguably, the best thing that comes from this approach is that the benefits are shared between the customers as well as between the postal company. Why? Because having a fixed location to pick your parcel in a contactless way benefits your own time management.

If we look statistically that employed adults are the ones who order things the most, and they mostly work at some location other than their home, while having in mind that the delivery men are also working shifts at about the same time – how is it possible for a person to receive their packages? Other than having luck with someone else being home, there just isn’t.

And to be honest, in most cases ,you’d respect your own privacy and don’t want your colleagues to see what goods you receive at your workplace.

Well, delivery parcels working 24/7, placed in fixed area locations from which you are free to choose one on your own, are the best possible solution to the discussed problem.

Keeping a track with time

Ok, now that we got the introduction part right, let’s move to the technical topic of this case study. What kind of digital solution was offered by the Croatian Post for the e-commerce industry needs?

It is the HP Paketomat plugin – software extension available for the web shops, completely free. Basically, what HP’s offering is to add one additional delivery option to customers of their web shops, the one where they can forward their package to the Paketomat locker’s location of their choice. It is currently provided for the custom integration and WooCommerce platform, as well as Magento and Presto development on the way provided by Lumen Spei ltd.

The plugin itself is a free one, although the contract between the web store and HP is obviously needed because of the physical part of postmen picking up and delivering parcels, as well as the whole operating procedures you’d get along the way.

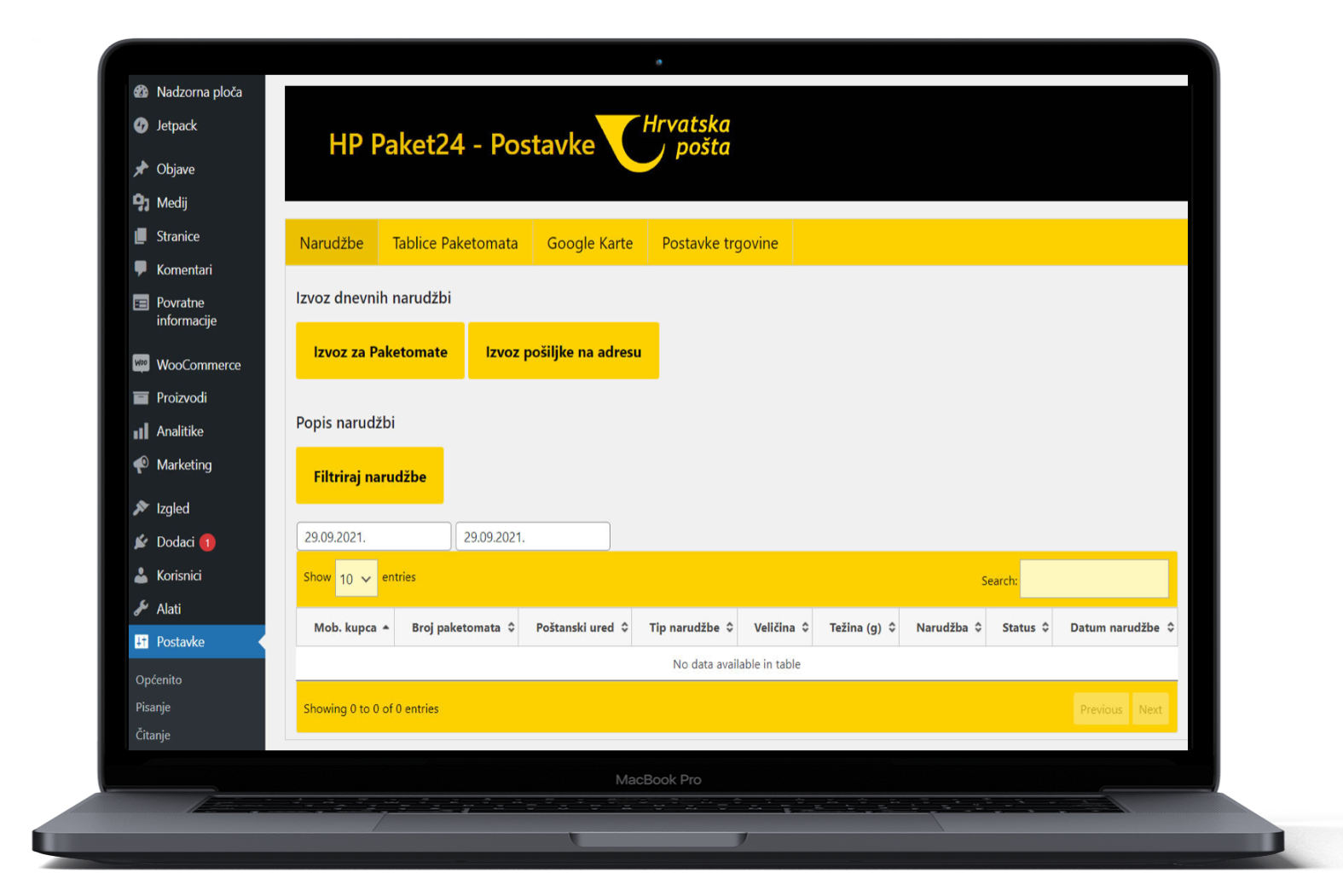

The logic behind the plugin is the following: software extension is used to automatically generate a csv (xls) compatible file filled with the orders placed throughout the day. That file is meant for uploading onto the Paket24 web application of the Croatian Post throughout the day, sort of a home system for all of the web based orders coming to HP, so that the prepared parcels with orders can be processed, collected and delivered.

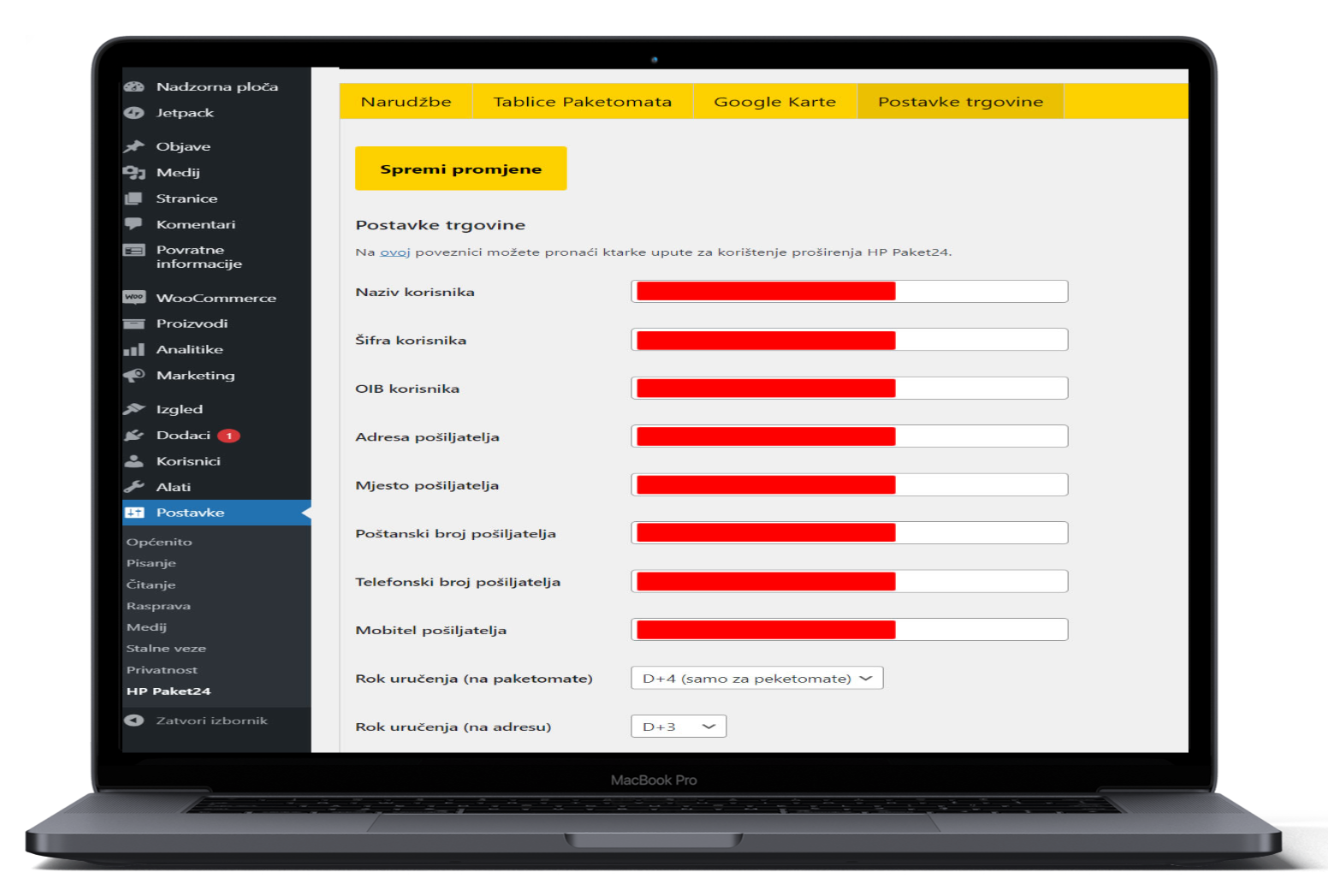

Within the plugin settings, each user can enter other data necessary for the extension to work properly as well:

- Store settings – adding sender information, which will be printed on the address book. Within the mentioned menu, there is also the option of choosing the delivery deadline to Paketomat locker or delivery to the address that depends on the concluded contract.

- Package tables – where it is possible to define delivery prices for each individual parcel shipment for a parcel locker, and the current unique price of delivery for Package24 shipment delivered to the address

- Google Maps – where each web store enters its API key for the correct display of the map. Google offers an initial display of up to 200USD which most small and medium-sized businesses cannot spend. In the case of an empty field in the “checkout” process, the parcel locker map does not appear, but the tabular display of parcel machines within a radius of 10 km from the user’s geolocation point is shown

The process as a whole is automated on high level, as the delivery men come to pick up the ordered parcels prepared for the delivery, and then rearrange them into specific “hives” in a means of Paketomat lockers across the country.

Tetris packing algorithm solves your problems

“To unlock the potential value of enhanced data access, postal players will certainly need to invest in advanced analytics and optimization systems. They can do so through external purchase, such as for basic route optimization algorithms, or via in-house development, such as for customized tour planning software.” – McKinsey report.

The plugin includes the so-called “Tetris packing algorithm” which does exactly what you’d say it does. Imagine an empty box, a parcel for delivery. If you have all of your articles in a web store defined by a means of their dimension (height, width, length), the developed algorithm in the background calculates all of the mentioned and provides the store with a direct solution, a parcel of exact size needed.

There are 5 different box sizes being offered:

- XS (9x16x64 cm)

- S (9x38x64 cm)

- M (19x38x64 cm)

- L (39x38x64 cm)

Even though, if you have a store with, let’s say 10,000+ items, it may be a problem to measure and type every item’s dimensions all the time, especially having in mind that there are new ones coming along.

Therefore, the solution is provided to a web shop’s Admin to mark the whole (sub)category of items.

Let’s take a look at the makeup category, for example. Makeup consists of generally small items that you could, realistically, put a lot of into one parcel. Therefore, a whole subcategory of eyeliners could be marked up for an XS delivery. Problem solved.

Paketomat and similar machines really do seem like the future has already knocked at our doors. Devices are operating 24/7 and are being opened via an SMS message containing a code.

Once you are standing at the locker, put a code inside its interface screen and it will open the container which, you guessed it, contains your parcel.

The postal sector is one of those who are really putting their efforts into stepping up their game in this new digital century. The main thing they are trying to trigger here is the digital mindset.

Their customers must be willing to embrace the upcoming changes, which may not be so easy at first as it isn’t with the breakage of any routine, but once you get used to it, there is usually a consensual no going back term.

Let’s take a look at the comparison below to understand a digital mindset movement against the past progress of postal services.

As the Parcel and Postal Technology International states, the postal sector has been going through waves of change since the onset of the digital economy in the early 1990s and the response to these challenges can be characterized in three phases:

- 1990s-2005: Productivity and diversification

- A focus on automation and consolidation of operations in the context of significant re-regulation. Start of diversification into data documents and digital services.

- 2005-2015: Digital to core

- Continuing automation with increased emphasis on building digital interfaces both with customers and with delivery workers. The connected receiver and delivery worker are critical to future innovation.

- 2015 onward: Digital as a mindset

- Digital is no longer an additional process but is fundamental to all aspects of postal product offer and delivery.

To wrap things up, one picture as a food for your thoughts. There is no need for further explanation.

What should you do next?

Now when you’ve got a bit more acquainted with the challenges of digital transformation, it’s time to take the first steps.

The best approach would be to consult with a digital transformation expert. There is simply too much to be done and rebuilt, and tasking your tenured employees and managers with planning and executing digital transformation may be counterproductive.

For this entire process to finish successfully, you need to have a fresh pair of eyes on your platforms, tools, data, processes, and technologies you’re using. Be sure to keep an open mind, as there will almost always be a need for some kind of critical change.

Finally, if you need a helping hand with digitally transforming your company, look no more. Lumen Spei ltd. has a track record of successful digitization projects, and we’re looking to help more companies reach all their business goals. Feel free to contact us!

Author: Domagoj Vilović